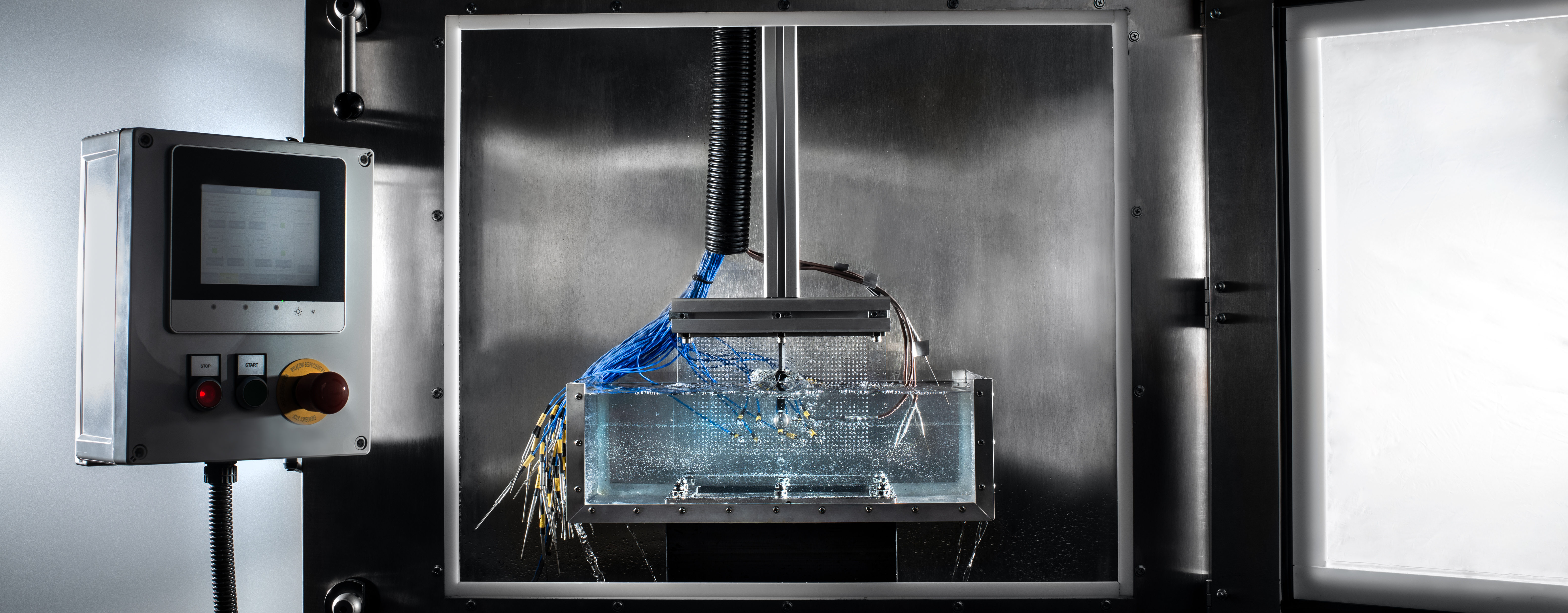

Experimental investigation

All the experimental activities of the CoolFood project were conducted using the dedicated test rig. That experimental rig was designed to test the fluid flow and heat transfer in the hydrufluidisation freezing process. The rig consists of two main subsystems including a coolant preparation loop and a hydrofluidisation chamber. In addition, these parts are installed in one compact rack. The numerous measurement instruments, such as thermocouples, pressure sensors and precise Coriolis-type mass flow meters, are installed in both mentioned loops. The hydrofluidisation chamber walls are equipped with the transparent windows. Such a design of the hydrofluidisation chamber enables the coolant flow field measurements by means of the Particle Image Velocimetry (PIV). Inside the hydrofluidisation chamber, the sample attachment system was installed. In particular, the analysed samples are mounted to the stainless steel frame positioned by two step motors. Moreover, those step motors are used to simulate the samples motion as in the industrial scale system.

Numerical investigation

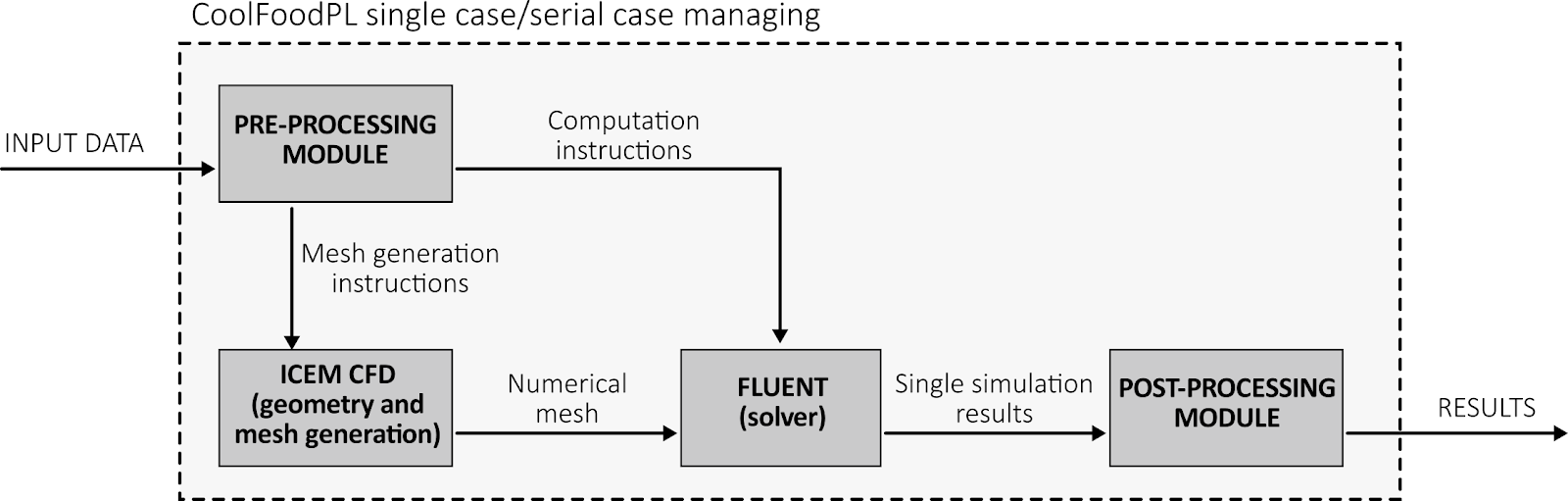

For the purpose of numerical analyses, the CoolFoodPL platform has been developed, allowing for efficient calculations. The subsequent stages of the analysis, i.e.: building the geometry of the system with the numerical grid, numerical calculations and the generation of selected results, are performed automatically by the program. The developed platform uses the commercial ICEM CFD software for generating numerical grids and FLUENT solver for numerical calculations. The operation algorithm of this tool is shown in the figure below.

The algorithm of operations performed to conduct numerical simulations.

The CoolFoodPL platform has been integrated with this website. After logging in, users are able to launch thermal and fluid flow calculations for the geometric and flow conditions they have set. This demo version allows to conduct the simulation for one of several available food products.